Brinkmann Mortar and Floor Screed Pump Technologies

Compressed air conveyor for screed applications

A compressed air conveyor operates according to the plug conveyance principle and is ideally suited for conventional screed applications. Some of the compressed air enters the pressure reservoir as header air and is mixed with the material to be conveyed, while the remainder enters the pressure line in order to separate the material into plugs and push them along the hose.

Site mixes (water, aggregate, binder) are added to the mixing vessel and then conveyed to the discharge tripod by compressed air.

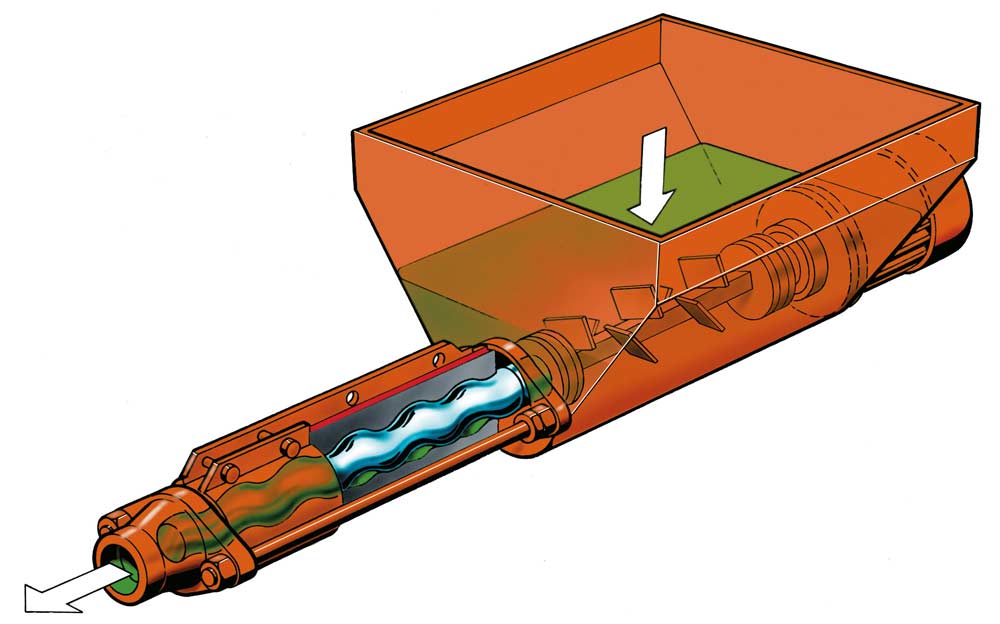

Worm pump

The material flows steadily out of the feed hopper and into the screw conveyor assisted by the mixer shaft. The conveyor consists of a rotating steel shaft (rotor) and a flexible rubber housing (stator), and the delivery rate and pressures depend on the geometry of these parts. These durable worms have a robust design and are capable of conveying high viscosity materials.