Plutonic Gold Mine, West Australia

May 17, 22

The Plutonic Gold Mine belongs to the Canadian Barrick Gold Corporation, i.e. the second largest gold producer in the world. It is located in the Australian outback, approx. 950 km north-east of Perth, where temperatures between 5 and 50 °C are common.

The mine came into operation in 1987 as an open-cut mine, since 1995 underground mining has been in operation, and at present a further 10 – 15 years’ operation is calculated. There are currently approx. 130 km of tunnels, with a diameter of approx. 6 m. The mining depth is at present up to 800 m, the extension below ground is approx. 1.5 km x 3 km.

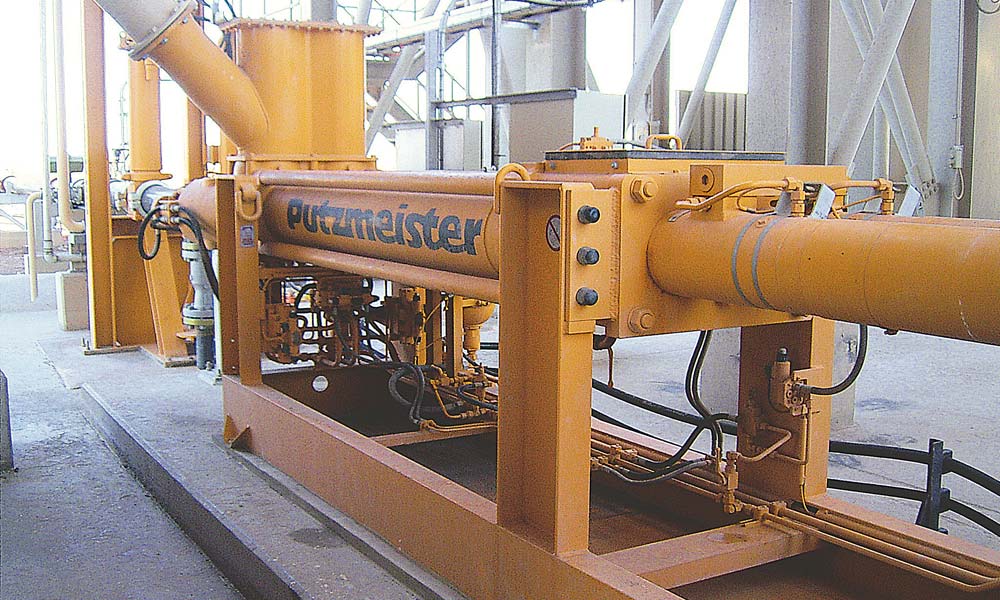

Pump with intake shaft

Annual production is approx. 360,000 ounces or approx. 10 t of gold. One tonne of ore yields 3 – 10 g of gold.

General view of paste treatment plant

Material transport

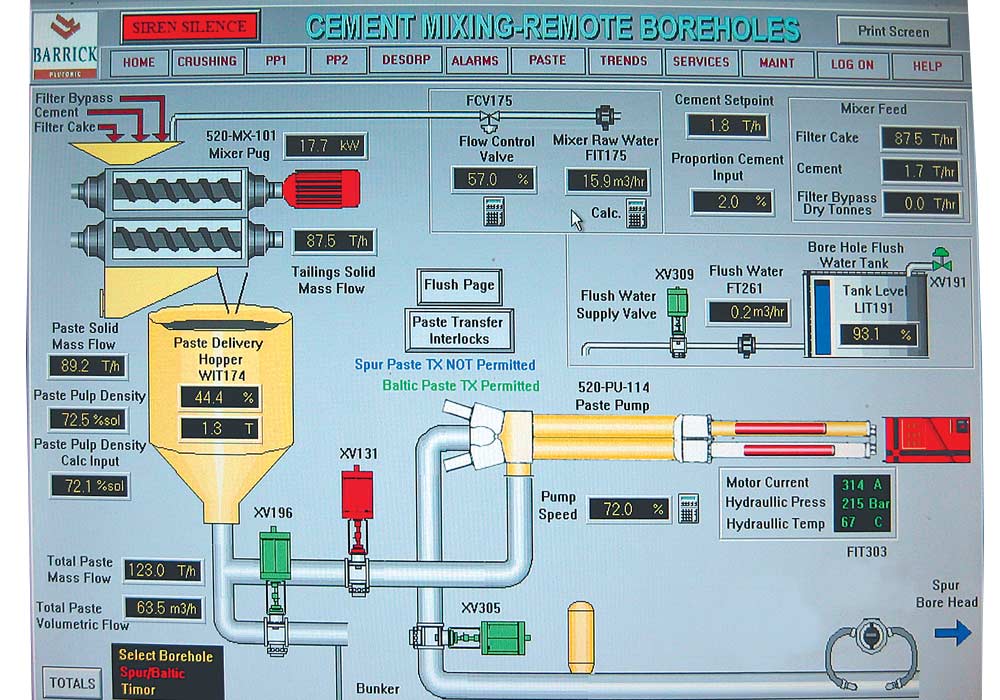

The medium is pumped via a DN 200 delivery line from the paste plant to two different bore holes. The delivery distance to the first bore hole is 500 m. The second is located another 500 m away, resulting in a maximum delivery distance of 1000 m overall.

Material/Description

The delivery medium is dewatered tailings with an average dry solids content of 73.5 % by weight. This paste contains 2 to 5 % cement, granulation ranges from 7 to 220 μ. Machine equipment HSP 2180 HPS, HA 315 E, HPD 200/750

Delivery quantity

The delivery quantity is max. 80 m3/h, the delivery quantity of the pump, however, is determined by the level in the delivery hopper. The duration of operation is 24 h/day with utilization of approx. 10 days/month.

Delivery pressure

The maximum delivery pressure is 80 bar and is achieved with a maximum dry solids content of 73 % by weight and a delivery distance of 1000 m.

Pipeline length/diameter

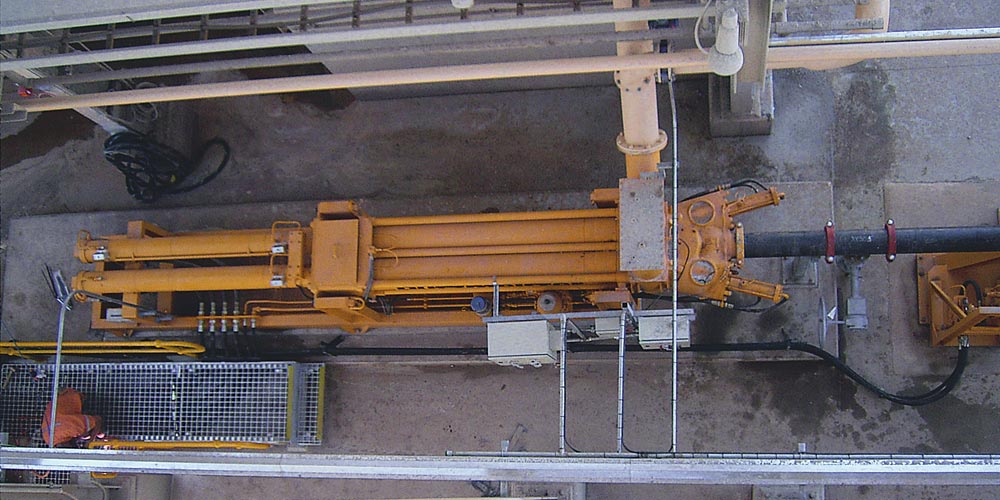

The delivery line has an outer diameter of 219.2 mm, and a wall thickness of 11.2 mm. A hydraulic power damper (HPD) is located directly after the pump to reduce vibrations and jolts in the delivery line.

Flow diagram with mixing screw, supply tank and high-density solids pump

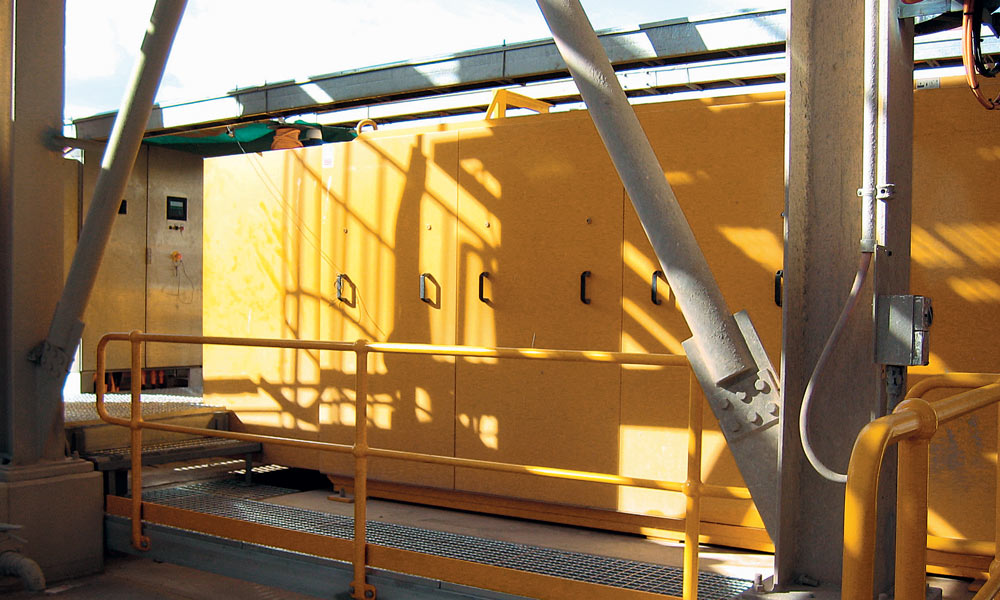

Hydraulic unit with control cabinet

General overhead view of pump with emergency drain valve between pump and power dampener

Power dampener with delivery line